The pet food market continues to expand, and more brands are entering the space to meet increasingly diverse consumer needs. In this environment, OEM manufacturing—where a trusted partner develops and produces products on your behalf—is an attractive option for many pet food companies, especially those that do not operate their own factories.

That said, OEM development comes with challenges, including selecting the right manufacturing partner and managing cost transparency. In particular, keeping product costs under control while maintaining high quality is critical.

In this article, we explain the typical costs involved in overseas pet food OEM development—and practical ways to reduce costs without compromising quality.

What Is Pet Food OEM/ODM?

Pet food OEM (Original Equipment Manufacturer) refers to products that are manufactured under another company’s brand name and sold as that brand’s products.

In other words, the manufacturer produces pet food not under its own brand, but under the brand of the client (your company). In many cases, the client decides the manufacturing requirements and formula, and the manufacturer produces the product according to those requirements.

This means you can develop and sell your own branded pet food even if you do not own a manufacturing facility.

OEM Manufacturing Challenges Becoming More Complex

Key Issues OEM Development Must Solve

Cost optimization

Move away from high domestic OEM cost structures and secure cost competitiveness while maintaining quality.

Stable supply chain

Build stable ingredient procurement and production systems that are not vulnerable to geopolitical disruption.

Product differentiation

Establish a foundation for product development that delivers uniqueness and added value that works in both domestic and overseas markets.

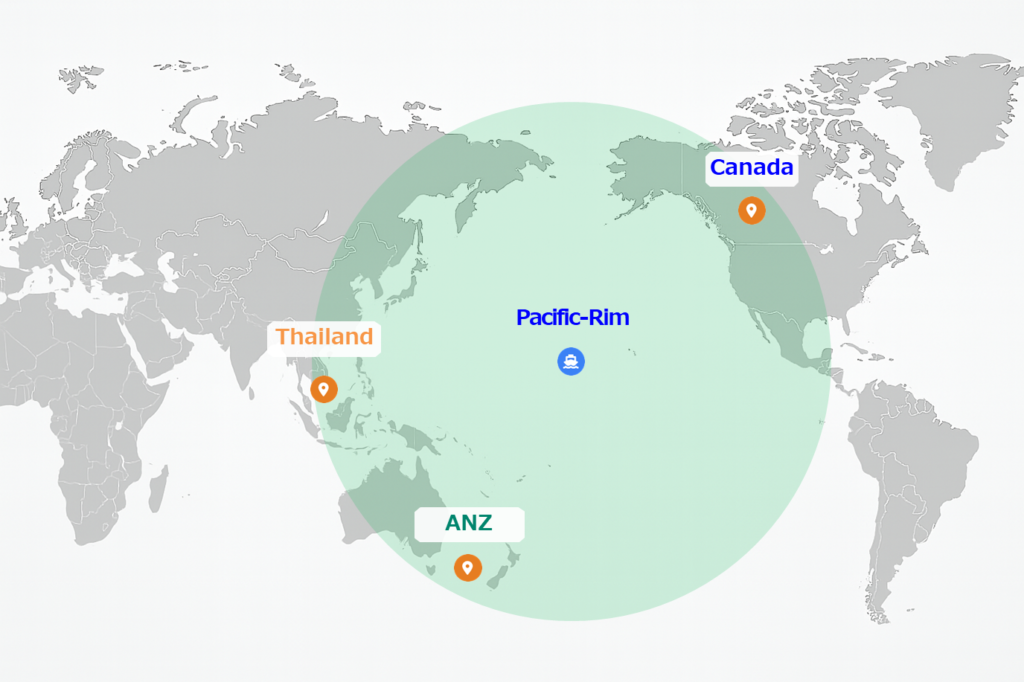

Solution: Leverage a Pacific-Rim OEM Network

- Completely avoids Red Sea / Suez Canal route risks.

- Flexible ingredient sourcing by leveraging each region’s strengths.

- Reduces the risk of ending up with the same recipes as competitors.

- Strengthens BCP through diversified sourcing and production regions.

Pet Food Categories Available for OEM Development

| Category | Dog Food | Cat Food |

|---|---|---|

| Dry food | ✓ | ✓ |

| Freeze-dried food | ✓ | ✓ |

| Air-dried food | ✓ | ✓ |

| Retort pouch (wet) | ✓ | ✓ |

| Treats | ✓ | ✓ |

Through our pet food OEM support, we work with OEM manufacturers across the Pacific region to develop the above products. Each category can be produced in a wide range of formats, formulations, and nutritional profiles—and in most cases, OEM development is possible.

For example, for dog food, we can develop products tailored to different life stages such as adult, puppy, and senior, as well as products designed for specific health needs.

Reference Cost Examples for OEM Development

| Product | Unit Price | MOQ | Minimum Order Value (EXW) |

|---|---|---|---|

| Thailand dry pet food (standard) | JPY 315.5/kg | 4,000 kg | JPY 1,262,000 |

| Australia dry pet food (premium) | JPY 445.5/kg | 10,000 kg | JPY 4,455,000 |

| New Zealand dry pet food (premium) | JPY 904.5/kg | 12,000 kg | JPY 10,854,000 |

| Canada dry pet food (premium) | JPY 514.3/kg | 20,000 kg | JPY 10,286,000 |

Our Minimum Order Value (Our Past Quotation Example)

Based on past quotations provided to customers, we have offered a minimum order value of JPY 557,600 (EXW). In this case, the manufacturing unit price equates to JPY 139.4/kg.

However, the actual cost varies significantly depending on the ingredients, formulation, and order volume. For accurate pricing, we ask that you contact us for an individual quotation.

Our Minimum Order Quantity (MOQ)

Dry food

MOQ depends on the OEM manufacturer selected, but as a guideline, the minimum lot size starts from approximately 4 tons per order.

If you are considering smaller production volumes, please inform us in advance. We will prioritize proposing OEM manufacturers that can support smaller lots.

Other product types

| Product | Unit Price | MOQ | Minimum Order Value (EXW) |

|---|---|---|---|

| Freeze-dried food | JPY 7,200/kg | 600 kg/SKU | JPY 4,320,000 |

| Air-dried food | JPY 2,600/kg | 1,200 kg/SKU | JPY 3,120,000 |

| Retort pouch (wet) | Case by case | 3,000 kg/SKU | N/A |

Freeze-dried, air-dried, and retort pouch products use different production lines and processes, so MOQs vary. For example, freeze-dried products typically require 600 kg per SKU, while air-dried products require 1,200 kg per SKU. In general, MOQs are determined by the volume needed to operate production equipment efficiently.

Our Strengths and Key Features

We support your product launch with extensive experience across market analysis, recipe development, packaging, logistics, and overseas coordination. Below are our five pillars that connect planning through execution and results.

1) Product Planning

2) Strong Recipe Development Capability

3) Packaging & Contract Packing Support

4) Logistics & Customs Support

5) Smooth Overseas Coordination

Overseas Pet Food OEM Development Process

Our “Overseas OEM Pet Food Support” service finds suitable OEM factories in major production countries such as Thailand, Australia, New Zealand, and Canada, and supports product planning, development, production, and shipping on your behalf.

Main categories we handle

| Category | Dog Food | Cat Food |

|---|---|---|

| Dry food | ✓ | ✓ |

| Freeze-dried food | ✓ | ✓ |

| Air-dried food | ✓ | ✓ |

| Retort pouch (wet) | ✓ | ✓ |

| Treats | ✓ | ✓ |

We provide comprehensive support for developing a wide range of pet food types—including dry, freeze-dried, and air-dried—based on your requirements. The following is an example of our OEM support flow:

OEM development flow

1. Hearing

First, we listen to your goals and requirements in detail. We will ask about the target pet, product purpose, desired ingredients/formulation, price range, and other specifications.

2. Planning and proposal

Based on your input, we develop and propose the most suitable product concept. We incorporate market research and trend analysis to propose a unique and competitive product that aligns with your brand.

3. Quotation and product specification sheet

Once you are satisfied with the proposal, we submit a project quotation and a product specification sheet.

4. Review of similar samples (if available)

After the product specifications are finalized, we provide similar samples if available for your review. You can confirm quality, taste, aroma, and other aspects and share feedback.

Please note that samples may not be available in some cases.

5. Packaging specification

Once the product is finalized, we move to packaging specifications. We can pack into your existing designed packaging, or we can arrange packing into plain PP bags.

Contract packing support is also available.

6. Contract and purchase order

After final packaging confirmation, we proceed with formal contracting and order placement. Manufacturing begins once the order is confirmed.

7. Production and delivery

We manage quality control and the production schedule to deliver within your requested timeline. We also provide ongoing updates on progress and quality throughout the process.

Frequently Asked Questions

- QCan you manufacture the recipe exactly as we request?

- QWhat about the quality of raw materials used in overseas OEM production?

- QWhat kind of manufacturing facilities do overseas OEM manufacturers have?

- QWhat is the quality control system at overseas OEM factories?

- QHow long does it take from inquiry to completion of the final product?

- QHow long does it take from order placement to delivery?

Contact / Inquiry

Email inquiry

nagai@first-reach.org

We will reply within one business day.

Phone inquiry

+66 (0)6-1457-4310

Weekdays 8:00–17:00

Web form (24/7)

https://first-reach.org/en/contact/