Thailand is one of the world’s leading pet food exporters. Would you like to develop high-quality premium dog food and cat food—and produce it through OEM manufacturing—while keeping costs under control?

When companies develop original pet food in high-cost markets such as North America, Europe, the UK, Australia, or other developed regions, they often face the same challenges: high production costs, large minimum order quantities (MOQs), and difficulty securing consistent, high-quality raw materials. However, OEM manufacturing in Thailand can help solve these issues and open the door to new business growth.

In this article, we focus on OEM manufacturing in Thailand and propose a practical approach to pet food development, especially for small and mid-sized businesses.

Challenges in Pet Food Development

Across many countries today, pets are increasingly treated as family members, and the pet industry continues to grow rapidly. Within that industry, the pet food market attracts particular attention. At the same time, competition is intensifying, and brands must respond to a wide range of customer needs.

In many markets, demand is becoming more diverse. For example, more pet owners are seeking grain-free options, and there is growing demand for health-focused foods tailored to a pet’s condition or age.

While this diversification suggests market expansion, it also creates several common challenges for many companies.

High costs

For many businesses, OEM production in high-cost regions often creates serious cost pressure. One major reason is the large minimum order quantity. Many OEM factories require large MOQs—sometimes as high as 20 tons.

This can be necessary for production efficiency and line optimization, but for smaller companies and emerging brands, it creates constraints in cash flow and warehouse space.

In addition, labor costs are another challenge. In many high-cost countries, wages are high, which increases manufacturing costs and directly affects the final product price.

Securing high-quality raw materials

We often hear that some OEM factories struggle to secure enough high-quality raw materials, which can limit their ability to accept new orders or maintain stable production. There may be several reasons, but one factor is the global shift toward premium pet food.

In recent years, pet owners increasingly seek foods that match their pets’ health needs and preferences—foods that are more nutritious and beneficial. As a result, more manufacturers focus on raw material quality and safety, and securing consistent, high-quality ingredients has become more difficult.

Barriers to entering the market

In many pet food markets, large companies dominate much of the industry, so it is not easy for small and mid-sized businesses to enter. Success requires not only manufacturing cost control, but also steady long-term efforts such as building brand awareness, earning consumer trust, and running ads and campaigns.

To support this, it is effective to provide credible information related to quality and safety. Small and mid-sized businesses must implement thorough initiatives in quality control and raw material selection. It is also important to communicate clearly with customers about brand values and commitments.

Why You Should Choose OEM Manufacturing in Thailand

We propose that customers consider developing and producing dog food and cat food in Thailand through OEM manufacturing. Why Thailand? Below are the key reasons.

Proven performance as a top global pet food exporter

According to the Thai Pet Food Trade Association (TPFA), Thailand’s export value in 2021 increased by 27% year-on-year, exceeding 65 billion baht, positioning Thailand as one of the world’s top pet food exporting countries.

The top export destinations for Thai pet food include the United States, Japan, Italy, Malaysia, and Australia, and demand is also growing across many Asian countries.

As of July 2022, Thai pet food exports had already grown by 43% year-on-year, showing further momentum.

According to Dr. Chaninth Charinsarapong, President of TPFA, Thailand’s long-standing experience in canned tuna production—around 20% of the world’s canned tuna is produced in Thailand—has also contributed to the expansion of wet pet food manufacturing. Wet food production in Thailand has become increasingly active.

Easier access to high-quality raw materials

A large portion of the raw materials used in Thai pet food (fresh meat, grains, and seafood) can be sourced domestically, which supports stable production and global competitiveness.

Thailand’s diverse climate and land allow for the production of a wide range of agricultural products such as grains, vegetables, and fruits.

Livestock farming is also strong, making it easier to obtain fresh, high-quality meat. In addition, Thailand’s coastal geography provides abundant seafood resources that can be used in pet food.

Cost advantages

Thailand is known for relatively low production costs. Compared with many developed countries, this is influenced by lower labor wages and efficient access to raw materials.

For companies planning to launch new pet food products, this is a highly attractive advantage. Lower manufacturing costs help keep product prices competitive and strengthen market positioning.

These are the key reasons why Thailand is an appealing country for OEM pet food manufacturing. By producing in Thailand, you can maintain quality while reducing costs—and build stronger competitiveness in the market.

About Our OEM Support Service

Our OEM support service helps clients by identifying suitable OEM factories in Thailand and supporting the entire process of product planning, development, manufacturing, and shipping.

We support a wide range of pet food categories including dry food, retort (ready-to-eat), and treats, and we provide comprehensive assistance aligned with your needs. Below is the basic process of our OEM support.

1. Consultation / Requirements hearing

First, please share your requirements and vision. We will ask for details such as product purpose, target pet type, preferred ingredients or formulas, pricing range, and other key specifications.

2. Planning and proposal

Based on the information gathered, we propose the most suitable product plan. We incorporate market research and trend analysis, and provide unique, competitive proposals aligned with your brand.

3. Quotation and product specification sheet

Once you approve the proposal, we will submit the project quotation and the product specification sheet.

4. Review of similar samples (if available)

After specifications are confirmed, if similar samples are available, we will arrange a review. You can check quality, palatability, aroma, and share feedback for the final product.

Note: In some cases, sample provision may not be possible.

5. Packaging planning

After the product is finalized, we move to packaging. We can pack into existing designed packages, and we can also support packing into plain PP bags.

6. Contract and purchase order

After packaging is finalized, we proceed to the formal contract and ordering process. Manufacturing then begins.

7. Production and delivery

We manage quality control and production schedules to deliver within your requested timeline. We also provide updates on progress and product quality as needed.

Benefits of Using Our OEM Support

Using our OEM support service provides several advantages.

Access to wider proposals

With our support, you are not limited to one factory. You can compare and select from multiple OEM factories.

We propose product specifications and ingredient selections recommended by each factory’s R&D team, while also explaining each factory’s strengths. This multi-angle approach helps you build the most suitable product.

Introduction to Japanese veterinarians (if needed)

We collaborate with experienced veterinarians and can introduce them as needed. If you require professional advice on health and nutrition, you can incorporate veterinary input into the product development process.

Smoother communication with local factories

We support smooth communication with Thai OEM factories. Even with language and cultural differences, our support enables smoother project execution and reduces risks such as misunderstandings in specs and concerns about schedule management.

Support for optimal shipping methods and tariff preferences

In international trade, selecting the best shipping method and using tariff preferences is extremely important. We support these complex procedures and propose more efficient and cost-effective logistics and tariff reduction approaches.

ee web marketing consultation

We also help you think through how to position and communicate your new product in the market, and provide free web marketing consultation. Our team provides strategic advice for online sales and advertising to support product success from a marketing perspective.

Our Pet Food Development Case Study

Here is a real example from a client project. The client had been producing dry dog food at an OEM factory in the UK, but faced the following issues.

Challenge 1: Long logistics lead time

Because the UK is far from key Asian markets, it took as long as 3–6 months from PO issuance to delivery, even though the client had provided an annual forecast order plan in advance.

Challenge 2: Rising manufacturing costs

In addition, because production was in the UK, labor and raw material costs kept increasing, and the client received price increase notices almost every year. Their recipe used fresh, high-grade meat, which further increased costs.

The client could not absorb the rising costs internally, so they had to raise retail prices—resulting in lower sales volume.

Our proposed solution

After hearing the issues, we proposed the following:

- OEM manufacturing in Thailand

➤ To reduce manufacturing and logistics costs

➤ To utilize tariff preferences where applicable under trade agreements - Comparison of two Thai factories (Factory A & B) capable of producing dry food from fresh meat

1) OEM manufacturing in Thailand

Labor costs in Thailand are often significantly lower than in many developed countries. Also, many key ingredients can be sourced domestically in Thailand, which helps reduce manufacturing costs.

Thailand is also geographically closer to many major markets, allowing reduced logistics costs. In addition, lead time from ordering to delivery was shortened to about two months.

In some cases, tariff preferences can also reduce import duties depending on the destination market and applicable trade agreements. As a result, the client achieved significant cost savings.

2) Comparing Factory A and Factory B

We proposed two OEM factories capable of producing dry dog food from fresh meat.

Factory A had a strong reputation for quality but higher pricing. Factory B offered lower pricing but was relatively new as a facility.

We organized and shared this information with the client, held Zoom meetings with each factory, and facilitated smooth communication to support decision-making.

This is how we provide multiple options and help clients find the optimal solution—this is the core value of our OEM support.

Frequently Asked Questions (FAQ)

- QWhat types of pet food can you develop and manufacture through OEM?

- QWhat is the minimum order quantity (MOQ)?

- QCan you manufacture exactly according to our desired recipe?

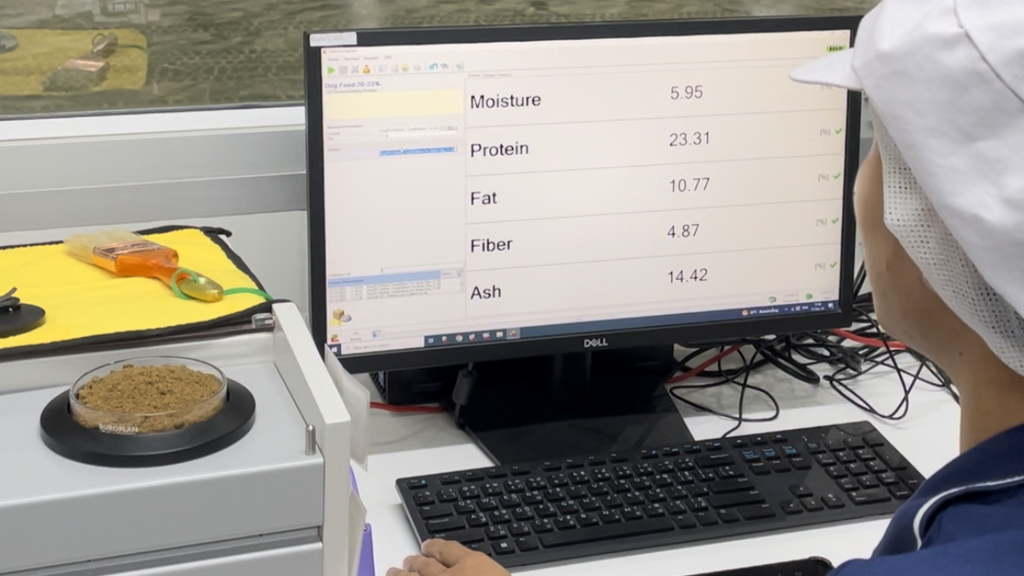

- QWhat is the quality of raw materials used for OEM production in Thailand?

- QWhat manufacturing equipment do Thai OEM manufacturers have?

- QWhat is the quality control system in Thailand?

- QHow long does it take from inquiry to a finished product?

- QHow long does it take from placing an order to delivery?

- QDo you provide logistics support (Thailand to Japan / overseas)?

Contact / Consultation

If you have any questions or would like to discuss our OEM support, please feel free to contact us anytime.

How to contact us

Phone: +66 (0)61-457-4310

You can call our staff directly.

Email:

Please send an inquiry email to our representative. We will respond with detailed answers to your questions and requests.

Information to Prepare Before Contacting Us

After you contact us, we will hold a detailed discussion based on your interests and needs. At that time, we will ask about the following:

- Project overview

Please share the purpose and outline of the product or project you want to develop. - Requirements and preferences

If you can tell us your desired specifications and budget, we can provide more concrete proposals. - Schedule

Please let us know your target timeline and desired launch timing.

We value close communication with our clients and will provide maximum support to help ensure your project success.